Turnkey Packaged Two-Pass RO and EDI System for Ultrapure Water Production

AMI custom-engineered water treatment solution designed to produce 20 GPM of USP rated ultrapure water (UPW) for pharmaceutical use in the north-central United States was successfully installed and implemented in 2020. The system, which was designed to fit the dimensions of the client’s available room, was fabricated in modular sections and tested at Applied Membranes, Inc. in California, then transported and reassembled, installed, and re-tested at the client’s facility.

The municipal city water feed is first pretreated with water softeners, carbon filtration, sodium hydroxide injection for CO2 reduction, and 5 micron depth filters before the reverse osmosis purification. The RO product water is then treated with a second pass of reverse osmosis followed by electrodeionization, ultraviolet disinfection for TOC destruct, and a final polishing 0.2 micron absolute filtration. The UPW production solution also incorporates a sanitization system utilizing continuous ozone sanitization for continuous for chemical-free disinfection cleaning, with zero residual in the UPW loop.

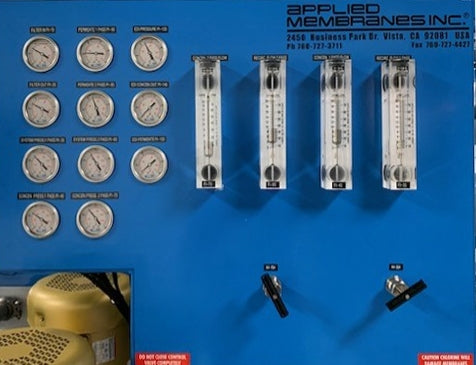

All stages of the water treatment system are controlled by a central PLC controller for automatic operation and extensive water quality monitoring instrumentation.