RO Water Treatment

Industry Leader in RO Expertise and Membrane Applications Since 1983™

For nearly four decades, Applied Membranes has been on the forefront of reverse osmosis technology, utilizing all improvements in the evolving techology and incorporating these into our product lines to offer the highest levels of performance and reliability available today. AMI designs and manufactures membrane elements for a wide variety of applications and water challenges. Our understanding of the membrane technology is reflected in our reverse osmosis systems, resulting in water treatment solutions that give the highest levels of performance available in the market today.

What is Reverse Osmosis?

Reverse Osmosis (RO) is a membrane separation water purification process in which feed water flows along the membrane surface under pressure. Purified water permeates the membrane and is collected, while the concentrated water, containing dissolved and undissolved material that does not flow through the membrane, is discharged to the drain.

The key requirements of Reverse Osmosis (RO) process are a membrane and water under pressure. Other requirements include prefiltration to remove suspended impurities and carbon to remove chlorine (damages the membrane).

Most membranes remove 90-99+ % of the dissolved impurities depending on the impurity and the composition of water.

Reverse Osmosis, combined with pre-filtration, is able to remove 90 to 99.99% of the dissolved impurities that reside in your water.

Reverse osmosis systems (RO Systems) remove salts, microorganisms and many high molecular weight organics. System capacity depends on the water temperature, total dissolved solids in feed water, operating pressure and the overall recovery of the system.

Benefits

Reverse Osmosis (RO) Systems Remove up to 99% of Total Dissolved Solids

Reverse osmosis is a membrane separation process in which feed water flows along the membrane surface under pressure. Purified water permeates the membrane and is collected, while the concentrated water, containing dissolved and undissolved material that does not flow through the membrane, is discharged to the drain. Reverse osmosis systems remove salts, microorganisms and many high molecular weight organics. System capacity depends on the water temperature, total dissolved solids in feed water, operating pressure and the overall recovery of the system.

Advantages of Reverse Osmosis over Conventional Processes

Compared with other conventional water treatment processes, reverse osmosis has proven to be the most efficient means of removing salts, chemical contaminants and heavy metals, such as lead, from drinking water. For waters with total dissolved solids of 200 or more, reverse osmosis is less expensive than ion exchange. Even at total dissolved solids of less than 200, it is preferred over ion exchange for removal of silica and organics. Compared with distillation, reverse osmosis use only a fraction of the total energy and does not have high temperature problems or scaling and corrosion. Today reverse osmosis systems have proven to be the most economical and efficient means of improving the quality of water.

Simple To Operate And Maintain

Applied Membranes reverse osmosis systems come assembled, factory tested and in ready-to-operate condition. They are designed for efficiency and are simple to operate and maintain. Besides regular monitoring and periodic membrane cleaning, membranes need to be changed every one to three years depending on water quality, size of the system and pretreatment. Pumps also require routine maintenance.

Product Lines: RO Water Treatment

AMI RO

AMI Brand Reverse Osmosis RO Membrane Elements for Tap and Brackish Water Sources. Learn MoreCommercial & Industrial RO

AMI manufactures Reverse Osmosis Systems (RO Systems) ranging from 24 gallons to millions GPD treating municipal, well, surface and sea water. Learn MoreSeawater Desalination

Designed to convert seawater to drinking water, these systems use high quality RO reverse osmosis seawater desalination membranes. Learn MoreRelated Applications: RO Water Treatment

Agriculture & Landscaping

Applied Membranes has manufactured thousands agriculture water treatment systems, producing millions of gallons of water world-wide with chemistry designed to increase crop quality and yield. Our list of successful installations includes Del-Rey Avocado, Sun Pacific, and many more.

Beverage & Bottled Water

Water is the primary ingredient of all beverages, and water quality is a key factor in the quality of the beverages that are produced. High quality water is essential to achieving a consistently great tasting end product.

Applied Membranes has been part of the beverage industry for as long as we have been in business. AMI systems are currently producing water used in beverages world-wide, including many of the leading breweries, beverage and bottled water companies. Our list of successful installations includes PepsiCo, Coca Cola, Cott Beverage, Glanbia, Nestle, Sparkletts, Niagara Water, Stone Brewing, Anchor Brewing, Firestone Walker Brewery, Four Horsemen Brewery, Belching Beaver Brewery, Driftwood Brewery, Stateside Vodka, and many others world-wide.

Boiler Feed Water

AMI Membrane has been designing systems for boiler feed water and power generation since 1983. Our expertise allows us to tailor water treatment systems designed to meet all of these water challenges as they apply to your specific application. AMI systems are operating in major power facilities world-wide, including: SDG&E San Diego Gas & Electric Company, General Motors, Cedar-Sinai, Bahamas Oil Refining Company, and many more.

Learn MoreCar Wash & Rinse

Water quality is key to running effective and lucrative carwash operations. Not only is water used during the wash process, but it also has a direct impact on the lifespan of wash equipment and the effectiveness of soaps, detergents, and chemicals.

Salt, hardness, minerals, and other impurities in city water cause spotting, and customers expect a spot free shine when leaving a car wash. Reverse Osmosis demineralizes and purifies the water allowing you to achieve a spotless and sparkling clean result. Using treated water also increases the effectiveness of soaps and detergents by removing minerals which hinder detergent performance, allowing for more effective washing and savings in the amount of labor and supplies used. Demineralizing the water through RO, NF, or softening reduces equipment maintenance and downtime as well as prolonging equipment life by preventing sediment and scale build up.

A proper water treatment solution will directly impact your profits due to more effective washes, less labor for post wash activities, less equipment maintenance, and an improved final product for increased customer satisfaction.

Learn MoreChemical Manufacturing

Applied Membranes has in-depth experience of the unique requirements of chemical production and provides equipment for treating process water, boiler feedwater, utility water and the treatment of steam condensate. Our engineers can custom-design systems tailored to address the specific water quality and fouling challenges of your application, with long term reliability, cost effectiveness, safety and regulatory compliance requirements integrated into the design.

Learn MoreDisaster & Mobile Water

In emergency situations and disasters such as drought, flood, earthquakes, fire, or war, it is imperative to establish a safe and reliable supply of potable water immediately. Constructed inside rugged 40-foot, 20-foot, or 10-foot modular ISO containers or trailer-mounted, AMI disaster relief and mobile water treatment systems are portable, easy to deploy and operate, protected from harsh environments, and capable of producing potable water from virtually any fresh, brackish, or seawater source.

Portable containerized AMI systems are also suitable for establishing high-quality water supply in remote locations and can be temporary or permanent plants. These plants are built for longevity and have reliable performance.

AMI mobile solutions are:

- Customizable

- Scalable

- Mobile

- Durable

- Flexible

With solar powered operation and trailer mounted options available, AMI mobile water treatment systems are versatile and durable for use in almost any environment.

AMI system containerization takes advantage of a small footprint to treat water from virtually any source, at any scale.

We offer containers of varying sizes and capacities to ensure optimal efficiency for your application. Each AMI containerized solution is meticulously engineered to meet specific needs.

Contact us today to learn how we can support your project.

Learn MoreFood Processing

Contamination is a leading concern in the food and dairy processing industry, as it poses a direct threat to consumer safety. A reliable supply of clean water is crucial for rinsing food products and equipment, and AMI systems can be custom engineered to meet strict requirements.

Additionally, AMI offers custom membrane elements specially designed for the food and dairy industry, for concentrating milk and cheese whey, juice, maple sap, and other food products.

Applied Membranes has been serving the food and dairy industries since 1983 and has installed systems in many of the leading food producers worldwide. Our list of successful installations includes Bumblebee Foods, LLC, Dannon, Califia Farms, Sun Pacific, and many other food and dairy processors worldwide.

Hospitality

Customer experience is the driving factor for success in the hospitality industry, and this is directly impacted by the quality of water used in food service or provided to hotel guests. Improving the quality of your water will upgrade your guest's experience as they notice better tasting ice, water, coffee and vended beverages, as well as softer, brighter linens. Treated water is also a necessity to keep other amenities such as hot water, cooling towers, boilers, ice machines, and laundry services running efficiently and reliably. In addition to adding value to your operation, treating your incoming water can prolong the life and reduce maintenance needs for appliances and equipment in your facilities.

AMI has many water treatment systems operating in hotels, resorts and restaurants worldwide. Our list of successful installations includes Sheraton Beach Resort, Fiesta Americana, Grupo Posadas, Cozumel Hotel, Cotton Bay Club and many more.

Marine Desalination

Enjoy the freedom of producing clean, fresh drinking water from seawater and eliminating frequent marina stops to refill water tanks. Watermaker seawater desalination systems use reverse osmosis technology to treat virtually any seawater source into fresh, safe water which can be used for drinking, bathing, food preparation, deck and exterior wash-downs, and a variety of other uses.

Land based installations can be used to supply freshwater to marinas, hotels, resorts, military operations, off-shore platforms, and a large variety of other applications.

Learn MorePharmaceutical Water

AMI Water Treatment Systems are custom-engineered to meet all USP, Purified Water (PW), and Water For Injection (WFI) requirements. We specialize in turnkey systems that provide a reliable source of ultrapure water, fully compliant with USP XXIII regulatory standards, complete with third-party validation and supporting documentation.

Water is a critical component in pharmaceutical processes—essential for formulation, rinsing, sanitizing, cleaning, and production. Maintaining a consistent, high-quality ultrapure water supply while adhering to stringent USP XXIII standards is vital for operational success.

At AMI, our pharmaceutical water treatment systems are conservatively designed with a focus on efficiency, reliability, and long-term cost savings. Every system is built to ensure sustained performance and lower operating costs without compromising on water quality.

Water quality plays a crucial role in pharmaceutical manufacturing, clinical diagnostics, healthcare operations, and medical procedures. AMI solutions are trusted for critical applications such as water for injectables, dialysis water, sterile processing, lab water, and medication manufacturing—all while ensuring compliance with the latest ANSI/AAMI ST108:2023 standards. Since 1983, leading companies have relied on AMI for consistent water quality that meets the strictest industry regulations.

Product Line:

- Commercial & Industrial RO

- Mobile Water Systems

- Pilot Plants

- Custom Systems

- Media Filtration Solutions

AMI water treatment systems are installed in many globally recognized pharmaceutical companies, including AMGEN, Schering-Plough, Fresenius, Baxter, Chiron (now Novartis), and many more.

Trusted by Industry Leaders

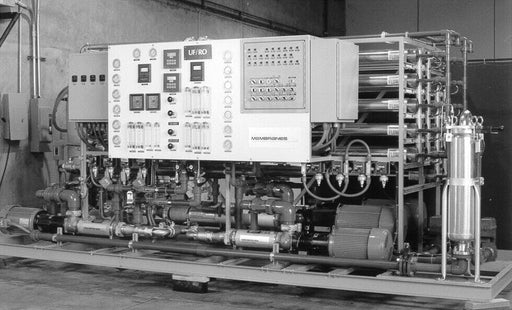

Pilot Systems

With over 40 years of hands-on experience, Applied Membranes offers custom-engineered water treatment pilot testing plants to fit your specific application. AMI pilot plant solutions are also available for lease.

Pilot water treatment systems are used for research, engineering, and technology validation, allowing companies to compare conventional or alternative water treatment technologies for new plant construction or existing plant expansion. Pilot water treatment can be used to test for regulatory requirements compliance, experiment safely, optimize designs and technologies used, and train water treatment professionals.

AMI can custom engineer and manufacture water treatment pilot plants for testing applications using Reverse Osmosis, Ultrafiltration, Nanofiltration, or Microfiltration technology for virtually any testing application including medical, pharmaceutical, USP, dairy, electrocoat paint, and more.

Seawater Desalination

From small to industrial sized, we offer a full range of both standard and custom engineered Seawater Desalination Reverse Osmosis Systems for applications ranging from yachts, cruise ships, boats to municipalities, hotels, resorts, military, off-shore platforms, and various industrial applications.

Applied Membranes' experience extends beyond standard seawater desalination systems. We have supplied complete seawater desalination SWRO systems with Energy Recovery, Data Logging, Containerized Systems, Explosion Proof Systems, Portable Systems for Military Operation, and many more from 150 gallons to millions of gallons per day.

Semiconductor Rinse Water

Semiconductor chip manufacturing processes and fabrication plants require ultrapure water at nearly every step. These fabs use millions of gallons of water daily for rinsing, cleaning and processing wafers. Proper water treatment design and water reuse helps manage consumption and drive more sustainable operations.

Treating raw water to the purity levels required in semiconductor manufacturing demands a robust sequence of advanced processes and water treatment technologies for removing contaminants, minerals, microorganisms, and trace organic and nonorganic chemicals, including other nanoscale particles. AMI systems for semiconductor rinse water are designed to produce ultrapure water (UPW) to be used in cleaning and etching processes and to wash and rinse semiconductor parts throughout the manufacturing cycle.

Brine water from industrial processes can be treated and reused instead of being discharged, reducing water waste. This brine may contain valuable minerals and metals which can be further concentrated and recovered.

Treating raw water to the purity levels required in semiconductor manufacturing demands a robust sequence of advanced processes and water treatment technologies for removing contaminants, minerals, microorganisms, and trace organic and nonorganic chemicals, including other nanoscale particles. AMI systems for semiconductor rinse water are designed to produce ultrapure water (UPW) to be used in cleaning and etching processes and to wash and rinse semiconductor parts throughout the manufacturing cycle.

Brine water from industrial processes can be treated and reused instead of being discharged, reducing water waste. This brine may contain valuable minerals and metals which can be further concentrated and recovered.

AMI has many ultrapure water treatment and high recovery systems operating in the microelectronics and semiconductor industry worldwide. Our list of successful installations includes Hua Yue Microelectronics and many more.

Learn More

Wastewater Reuse

The manufacturing industry is facing constantly increasing regulations and requirements for reduction of waste water. For many industries, the biggest impact on the environment is related to primary water consumption and wastewater discharge. Reuse of wastewaters represents a significant economic and ecological challenge for many applications including textile production, cooling water, car wash, chip manufacturing, landfill leachate, and more.

AMI can custom engineer a membrane water treatment system to recycle water and meet the reuse quality requirements for your application.

Learn MoreRelated Articles:RO Water Treatment

|

What is Reverse Osmosis? |

|

Reverse Osmosis Membranes and Systems for Low Tap Pressures |

|

Improving Water Quality Can Yield a Better Crop |

Experience: RO Water Treatment

Trailer-Mounted Seawater ROWPU Systems for UN Military Disaster Relief

| Flow Rate (M³/Day) | 720 |

|---|---|

| Flow Rate (LPM) | 500 |

| Flow Rate (GPM) | 132 |

Trailer-Mounted Seawater ROWPU Systems for UN Military Disaster Relief

SWRO System for Desalination Pilot Testing

| Flow Rate (M³/Day) | 191 |

|---|---|

| Flow Rate (LPM) | 132 |

| Flow Rate (GPM) | 35 |

AMI Custom-Engineered Pilot Test System to check feasibility for RO Seawater Desalination to supply municipal or other applications. The 2 pass RO...

View full detailsGround Water Remediation for US Army Base, Florida

| Flow Rate (M³/Day) | 379 |

|---|---|

| Flow Rate (LPM) | 263 |

| Flow Rate (GPM) | 69 |

AMI custom-engineered ground water remediation installation incorporating ultrafiltration and reverse osmosis technologies to remove pollutants fro...

View full detailsSeawater Desalination System for Resort Water

| Flow Rate (M³/Day) | 545 |

|---|---|

| Flow Rate (LPM) | 379 |

| Flow Rate (GPM) | 100 |

Water Treatment System Installation for seawater desalination from open sea intake to supply resort/hotel with potable water.

Ultrapure Water System for Microchip Manufacturing

| Flow Rate (M³/Day) | 1,635 |

|---|---|

| Flow Rate (LPM) | 1,136 |

| Flow Rate (GPM) | 300 |

AMI custom engineered water treatment system to supply ultrapure water for use in rinse water for microchip manufacturing in Hua Yue Microelectroni...

View full detailsRO System for Boiler Feed Water, Electrocoat Paint, & Automotive Plant Use

| Flow Rate (M³/Day) | 2725 |

|---|---|

| Flow Rate (LPM) | 1,893 |

| Flow Rate (GPM) | 500 |

description test

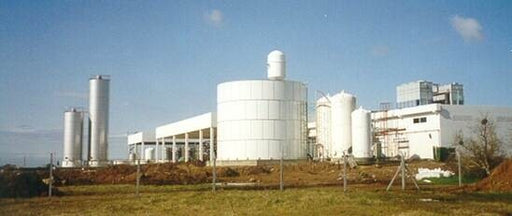

Reverse Osmosis System for Cheese Manufacturing

| Flow Rate (M³/Day) | 4,360,792 |

|---|---|

| Flow Rate (LPM) | 3,028,000 |

| Flow Rate (GPM) | 800,000 |

AMI custom-engineered water treatment project, fed by brackish well water, with a combined capacity 800,000 gallons per day of process water for u...

View full details

Sort by